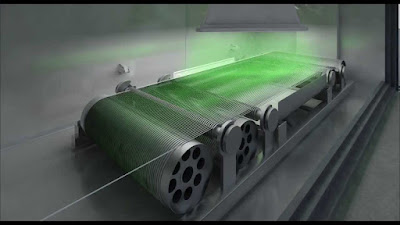

Electron beam (EB) coating has become a commonly used technology in a variety of production processes. This approach is used to create a thin coating on a variety of surfaces, including plastic, polymer, wood, automobile parts, and so on – which can be organic or inorganic. The coating works as a protective layer, forming a gas and moisture barrier, strengthening lamination bonding, allowing for reduced migration, and reducing corrosion. This coating is used to protect semiconductors used in electronic components, as well as in the automotive and aerospace industries, from corrosive environments by producing a chemical and thermal barrier. It is also utilised in the optics industry as an anti-reflective coating to improve the lens's efficiency. Anti-refractive coating minimises stray light by decreasing reflection in complicated devices such as telescopes, improving image contrast. In an eyeglass lens, it reduces eye strain, improves vision, and makes the wearer’s eyes more visible to others, which looks more attractive. Electron beam (EB) based coatings minimize stray light and reduce reflections, and hence are a preferred in a number of applications, such as binoculars, automotive, construction, and telecommunication.

It is also used in printing and packaging industries in the place of conventional ink. It is used for coating in both, flexible packaging & graphic art, as well as in rigid metal packaging. Also, electron beam (EB) based coatings allow for curing through thick films, which may be either pigmented or clear.

The demand for low-cost efficient coatings is driven by short lead time, high quality, reasonable prices and on-time delivery of materials. Hence, these are some of the major drivers of the global electron beam (EB) based coating market over the forecast period. Additionally, low energy consumption, consistent coating quality, low volatile organic compounds, rapid during and drying, abrasion resistance, and superior hardness are some advantages and properties expected to affect the electron beam (EB) based coatingmarket positively. Moreover, increase in the automotive industry, packaging industry, and printing industry will subsequently increase the market for electron beam (EB) based coatings. Rising adoption of certain electronics and communication devices, such as tablets, smartphones, LCDs, SSDs, and LEDs, which use semiconductors with electron beam (EB) based coating,directly contribute to an increase in its demand.

No comments:

Post a Comment